Although my marina employs isolating transformers for shorepower, I wanted the assurance of having total galvanic isolation.

I purchased a Zinc Saver isolator rated up to 100amps (double what is required).

I will install it about a foot from the shorepower socket on the GREEN or 'earth' wire.

I've had to fix a plywood block to the hull side in the engine room to fasten the isolator securely. The block is 3"x4" and is held in place with 3M 5200.

I wanted to test the unit before installation. Here is the process courtesy of Galvanic Isolator UK

Testing a Galvanic Isolator with Stud connections

To test a Galvanic isolator with connecting studs...

To test a Galvanic isolator with connecting studs...

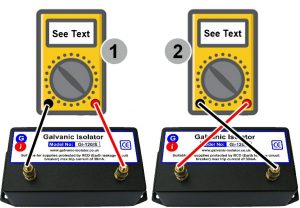

1). Set the multimeter to the Semiconductor Test or Diode Test position, and attach one crocodile clip to each stud. Wait 5 seconds then note the reading on the meter. The reading will typically be between 0.9 (Volts) and 1.6 (Volts).

2). Now reverse the connections. Wait 5 seconds then note the reading. Your Galvanic isolator is OK if the reading is similar (within about 10%) of the previous reading.

My readings were 9.7v and 9.4v in either direction.

I'll install it by carefully cutting the outer cover, cutting the green wire and fixing heat shrink marine terminals to both ends. Fix the terminals to the posts and it's done.